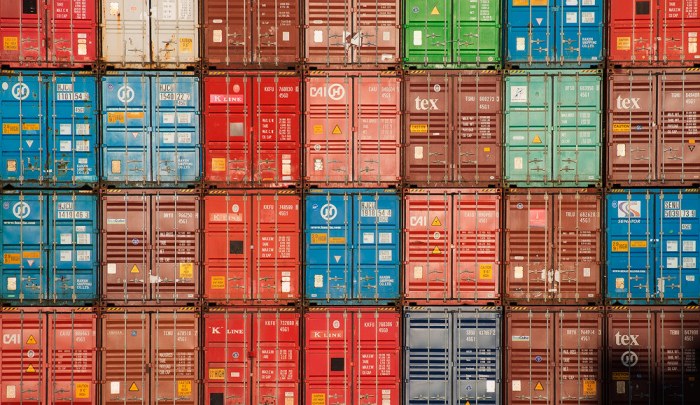

Nine organisations involved in the supply of goods to the UK have written to UK transport minister Grant Schapps this week to warn that the current levels of congestion at the country’s leading container ports could continue for some time to come.

The freight, logistics, shipping and ports organisations explained that COVID-19 and Brexit provide the backdrop to the chaos that has unfolded at the UK’s maritime gateways, with the first wave of the pandemic bringing disruption to global ocean shipping services; and more turmoil followed when different economies came out of lockdown at different times.

One consequence were delays in the return of empty containers from Europe to Asia leading to shortages, particularly at Chinese ports and whose full impact began to be felt as the sector entered its traditional period of high demand on east-west trade lanes in the early autumn, the group’s highlighted. And the problem has been further compounded by factors specific to the UK such as a surge in imports as the end of the Brexit transition period nears and also by significant quantities of COVID-related PPE which is adding to the strain on storage and warehouse capacity at the country’s ports.

In their letter, the signatories, which included the UK Chamber of Shipping, the British Ports Association, the Road Haulage Association, and Logistics UK, remarked: “Although we are hopeful that the current peak of port congestion has passed, high volumes remain and could persist for some months, running into the period of the end of the EU transition. Therefore, challenges remain.”

The letter continued: “The current situation has arisen in part from imbalances that accumulated over months. Reversing this accumulation is not an overnight task.

“Additionally, UK factors such as the imminent end of the EU transition period may well bring disruption, at least in the short term – an area where more urgent work is required and where container movement has until very recently received little attention in the government’s planning.”

While underlining that supply chain players were “seeking solutions ourselves” to issues and “are not complacent”, the letter called for urgent help from the government to relieve the congestion – including greater flexibility for trucks to operate on roads, increased access to the rail network for freight trains; and more long-term, the relaxing of planning regulations, providing scope for new warehouses to be built in proximity to ports.

Limited options for intervention

The Times reported today that Whitehall officials have acknowledged that the global container system, is “running hot” but have warned that their options for intervention are “pretty limited”. The officials insisted that the issue was being taken “seriously”, describing a 20% surge in imports at UK ports in private communications with companies.

“The government is monitoring the impact on critical supply chains and ensuing that there is capacity at the non-container ports as and where needed,” one message said. However, it said that “for legal reasons” the Department for Transport was restricted in the steps it could take.

Quoting importers, the newspaper highlighted that the global shipping crisis is causing freight costs to soar and that these will inevitably be passed on to consumers. There are already concerns that the congestion and delays at UK ports mean some toy deliveries will not arrive in time for Christmas, with consignments of scooters, Barbie dolls and other toys among those products reportedly held up.

Most shipments delayed

Some retailers say that as few as one in five shipments due in September and October have arrived. The problems have also led to high street chains reporting shortages of white goods such as washing machines and fridges, while building merchants are running out of supplies such as power tools, screws, timber and roof tiles, The Times added.

Freight forwarders have been reporting congestion issues since September at the UK’s largest container port, Felixstowe. Tim Stacey, CEO of home furniture retailer, DFS, which has used Felixstowe for three decades, told the newspaper that there was a “genuine problem” at the port and it was getting worse.

Nor are the problems at the ports only affecting retail goods – as can be seen from the decision by car manufacturer Honda to suspend production yesterday at its Swindon plant because of a “transport-related parts delay”.

Felixstowe issues continuing

In an update this week, the Port of Felixstowe said that “like other major container ports worldwide, Port of Felixstowe is still experiencing a spike in container volumes and dealing with the consequences of the ongoing Covid pandemic. In addition, we have had a high number of slow-moving containers of PPE occupying storage space.

“The current high volumes are expected to last into the New Year and we are working hard to minimise the impact on daily operations and to maintain vital supply chains.”

The port is reportedly still dealing with thousands of containers of personal protective equipment for health workers that have not yet been collected. The port noted this week that it has “been working with the Government’s principle forwarder to remove PPE containers as quickly as possible. Excess volumes have reduced significantly since the peak and should all be cleared within the coming week.”

Amid reports that the congestion at Felixstowe had spread to create congestion issues at other UK ports such as DP World-operated Southampton and London Gateway, DP World commented: “The confluence of Covid, seasonal trade, and Brexit is placing understandable pressure on the UK port network. Our teams at London Gateway and Southampton are working tirelessly to manage the additional traffic through our ports while maintaining our high customer service standards.”

Commenting on the current reports of maritime supply chain disruption, Tim Morris, CEO of the UK Major Ports Group, said: “The COVID-19 pandemic has caused unprecedented volatility in global supply chains. The impact is being felt across the world, including here in the UK.

“The situation at the UK’s ports is improving following commitment of extra resources, working closely with customers and ports across the UK taking on more traffic. However, we are not complacent. Improvements at UK ports will take time to work through supply chains, they remain very busy and the underlying problem is global.”

Risk to supply chains quantified

Analysis by business and insurance risk specialist Russell Group reveals that retail and engineering giants such as Asda, John Lewis, Tesco and Rolls-Royce face hundreds of millions of dollars of supply chain risk and exposure in the run up to Christmas – and beyond – caused by disruption at the UK’s largest container port, Felixstowe,.

As more and more companies highlight the risks to their supply chains and their ability to trade this winter caused by the current congestion and hold-ups at UK ports, particularly Felixstowe, Russell Group has quantified the risk exposure level of the top UK firms that import and export through the UK’s largest container port. Those risks are likely to continue beyond the run up to Christmas, with further disruption expected following the end of the UK’s Brexit transition period from EU rules from the end of this year.

The port has been experiencing a logistical logjam since the end of summer due to a number of factors – including unexpectedly high demand and oversubscription to container delivery and collection slots – that have created supply chain headaches for British companies in the run up to Christmas, adding to the current woes caused by the pandemic, with the possibility of a no-deal Brexit adding to the crunch in capacity, Russell noted.

Its analysis of the companies that import and export $9 billion of annual trade through Felixstowe reveals that the leading importers through the port of Felixstowe include: Asda ($433 million); John Lewis ($326 million); Tesco ($294 million); Marks and Spencer ($281 million); Capri Holdings ($241 million); Electrocomponents PLC ($217 million); Chanel ($171 million); APTIV ($141 million); Burberry Group ($137 million); and Jaguar Land Rover ($133 million).

Meanwhile, the leading exporters from the port of Felixstowe are: Rolls-Royce ($214 million); Diageo ($111 million); Bodycote ($64 million); GlaxoSmithKline ($27 million); Kaz Minerals ($19 million); B.E Wedge Holdings ($15 million); JCB ($13 million); Unilever ($12 million); APTIV ($11 million); Chivas Brothers ($11 million).

Russell Group CEO Suki Basi commented: “The large exposure of many leading British companies from the disruption at Felixstowe is real-time example of ‘Connected Trading Risk Exposure’. The disruption at the port creates ripple effects across the economy, from supply chain disruption for organisations through to potential higher prices for UK consumers.

“While the current pandemic has rightly forced many organisations to reassess their current risk management techniques, these figures, in our view, show that any effective risk mitigation plan needs to have a Connected Trading Risk Exposure strategy at the heart of it.”

Share this post: